1. Compatibility

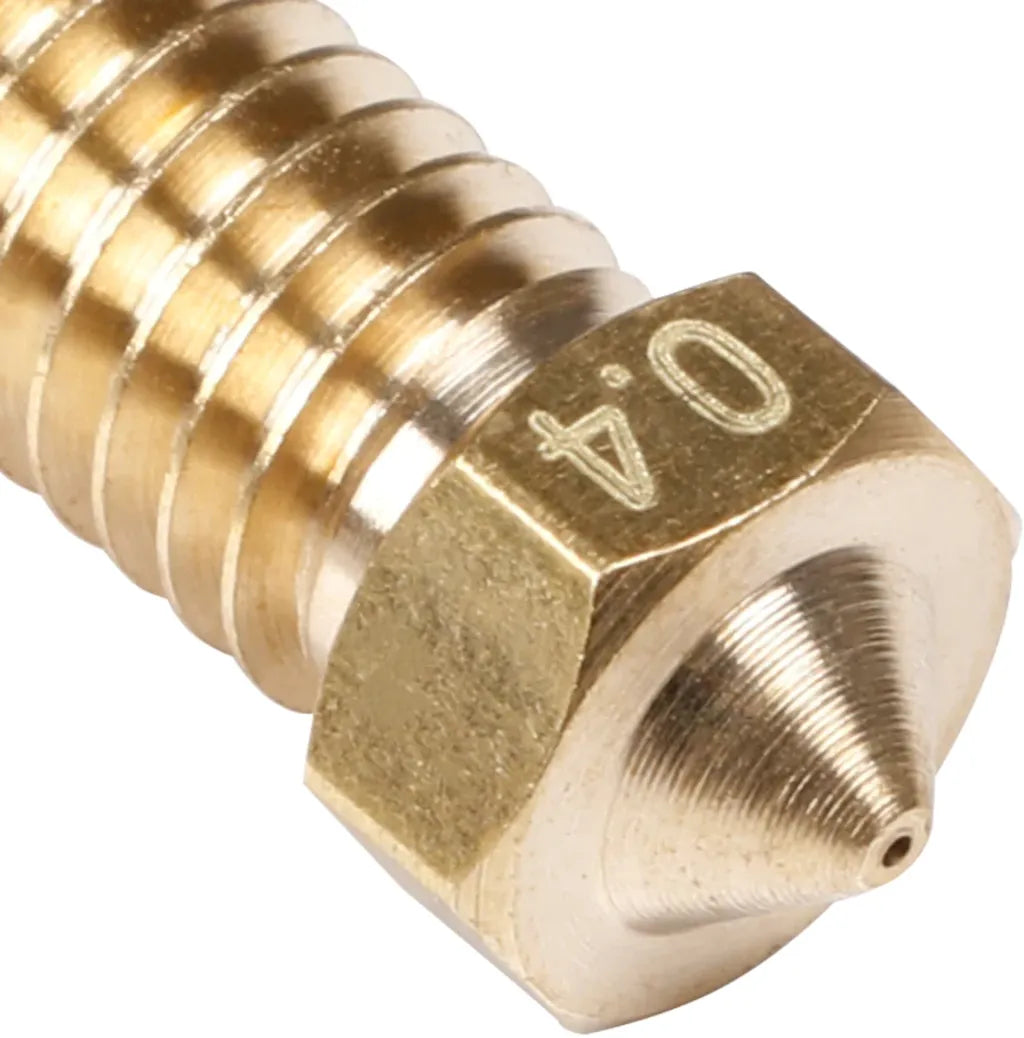

- The Anycubic Kobra 3 uses an MK8 threaded nozzle, which is a standard fitting across many 3D printers. So, you can use a 0.4mm brass nozzle that is designed for MK8 threading.

- When ordering, ensure that the nozzle specifically mentions compatibility with the Anycubic Kobra 3 or MK8 fittings to avoid any issues.

2. Advantages of Brass Nozzles

- Excellent Heat Conductivity: Brass has superior thermal conductivity, which means it can heat up and cool down quickly, improving extrusion consistency and reducing print times.

- Versatility: Brass nozzles work well with a wide variety of filaments like PLA, ABS, PETG, and others that aren't abrasive.

- Affordable: Brass nozzles are typically inexpensive, which makes them ideal for most users who are printing with common filaments and don't need a more specialized material.

3. Considerations for Using a 0.4mm Brass Nozzle

- Filament Compatibility: If you’re printing with abrasive materials (like carbon fiber-filled or metal-filled filaments), a brass nozzle may wear out more quickly. In such cases, consider upgrading to a hardened steel nozzle for greater durability.

- Printing Resolution: A 0.4mm nozzle is a good middle ground for resolution and speed. You’ll get a good balance between print detail and speed. If you need finer detail, you could switch to a 0.2mm nozzle, but it will require slower print speeds.

4. How to Install a 0.4mm Brass Nozzle on the Anycubic Kobra 3

- Step 1: Power Off the Printer – Ensure the printer is powered off and the hotend has cooled down before working on it.

- Step 2: Remove the Old Nozzle – If replacing an old nozzle, use a wrench or a nozzle removal tool to unscrew the old nozzle. You may need to heat the hotend slightly (about 150–200°C) to loosen it, but always be cautious when handling the hotend at high temperatures.

- Step 3: Install the New Nozzle – Carefully screw the 0.4mm brass nozzle into place. Be sure to tighten it properly, but avoid overtightening to prevent damaging the hotend.

- Step 4: Recalibrate the Printer – After replacing the nozzle, recalibrate the bed leveling. This ensures proper nozzle distance and optimal print quality.

- Step 5: Test Print – Perform a test print to ensure the new nozzle is working correctly and that extrusion is consistent.